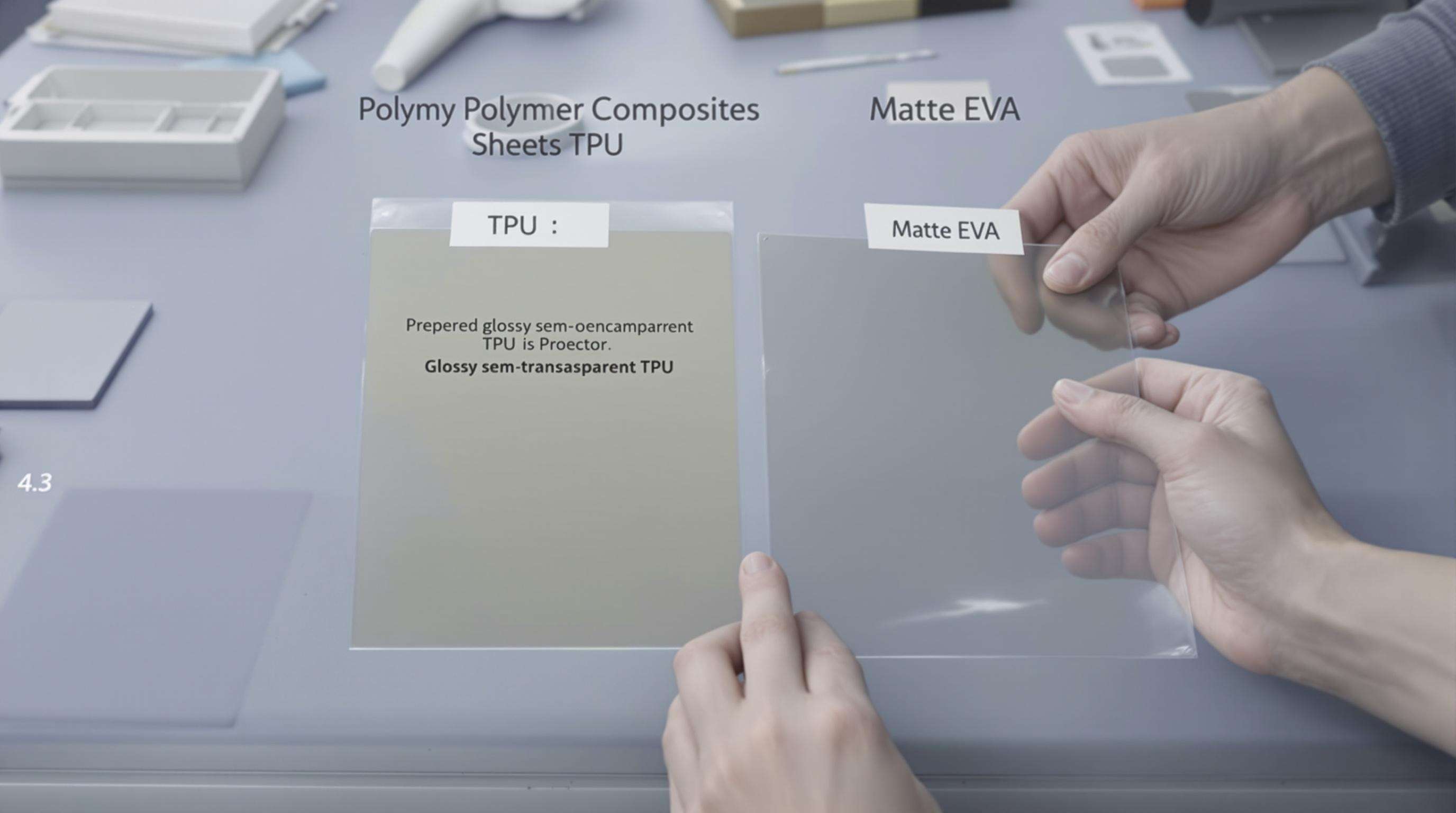

The selection of suitable materials is the keystone of the protector performance; it's the point where biomechanics (for the highest energy absorption at 1st impact) meets ergonomics (for the shortest travelling distance of the force to the backbone). Form-fitting polymer composites are prevalent in contemporary designs because their energy absorption characteristics can be tailored. Compliance to impact resistance standards such as EN 1621-2 limits even more the type of material used, and cost effectiveness prevaluates the choice between TPU (thermo plastic polyurethane) versus EVA (ethylene-vinyl acetate). The strict supplier qualification guarantees stabilization of raw material between production batches.

Thanks to sophisticated polymer composites such as a hybrid TPU-fiberglass layer or carbon-fiber reinforced plastics, the stiffness varies specifically in the respective protector zones. Those advances make it possible for new viscoelastic foams to degrade 72-85% of the energy developed during a high-speed impact, while being 15% more flexible that their traditional counterparts. Manufacturers are using close-mold process for composites, which will also help in reducing porosity that develops in the product, and this can negate the strength the product may have.

EN 1621-2:2014 stipulates that back protectors muster no more than a peak of 18 kN in 50J impact tests a parameter calling for materials that perform with the appropriate degree of compression-set. And with third-party lab numbers proving these TPU protectors are capable of 9-12 kN values of transmission, rather than the 14- 17 kN value for EVA; it's no contest. The 24% performance margin is directly related to lower risks of spinal injury in motorcycle collisions, as demonstrated in biomechanical simulations.

Although TPU is stronger, its $38/kg cost is three times the $12/kg price of EVA. TPU-EVA Hybridization: Material costs are lowered 40% by protectors which adopt zoned TPU-EVA Hybridization, without loss of certified protection levels. Life cycle analyses have proven that TPU’s 8-year longevity (compared to EVA’s 5 years) outperforms EVA by 19% over the 10 year time line, despite initial cost differences.

Top manufacturers audit polymer suppliers through a 12-point checklist:

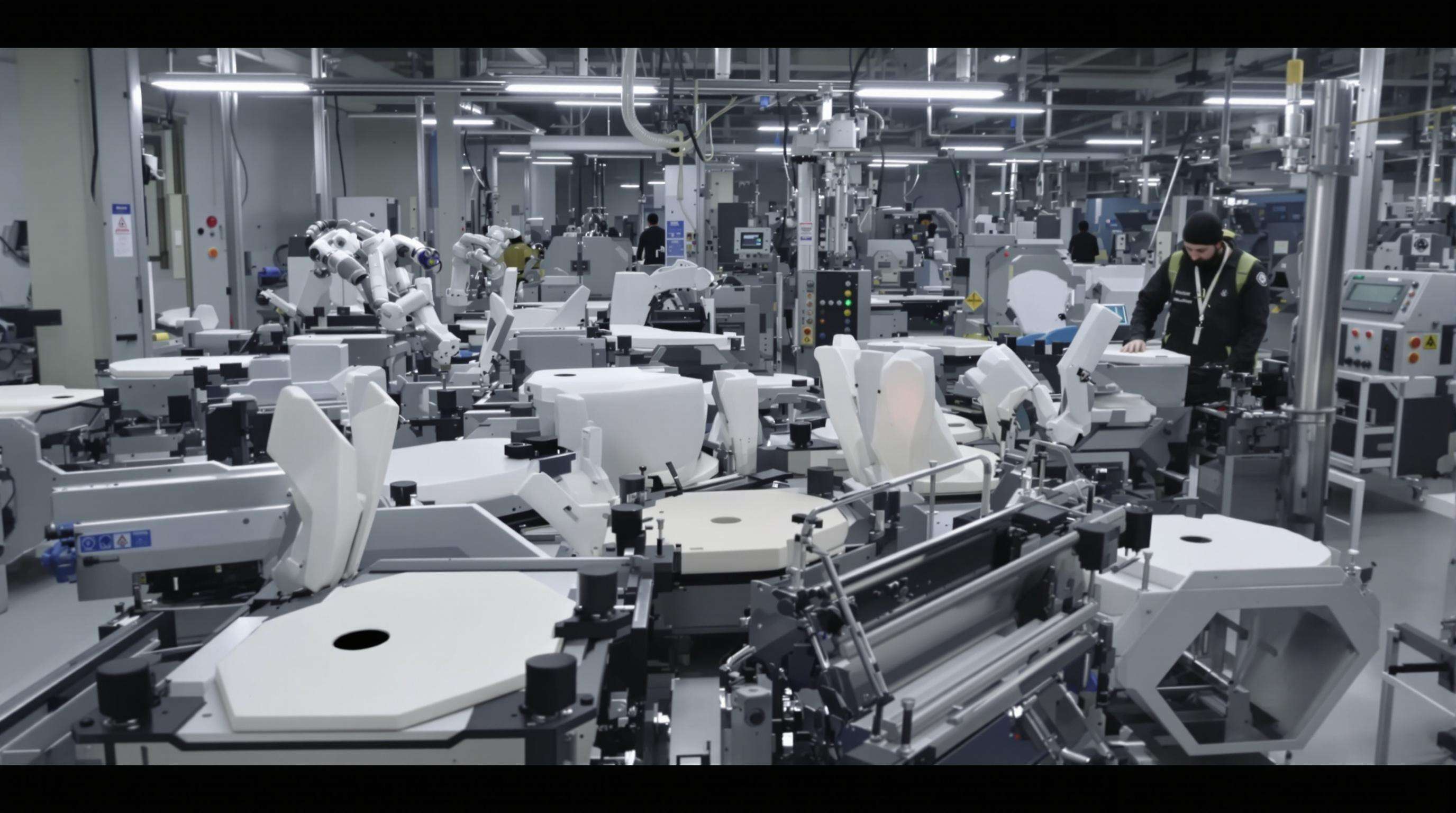

Back protector manufacturing relies heavily on advanced thermoforming techniques to balance structural integrity with ergonomic design. Three critical process optimizations dominate modern production workflows.

Vacuum Molded Vacuum molding is the most widespread production method for back protectors because is an economical process allowing for prototyping and mid-volumes. Recent developments have improved cycles by 30–45% with infra-red preheating of polymer sheets at 2.3x faster rate than the traditional approach. XXXX it was achieved due to optimal mold temperature (130–150°C for TPU composites) that reduces material rebound allowing maintaining constant wall thickness (1.2–1.5mm) on the curved surfaces. Today automatic sheet feeders allow continuous operation, reducing dead time between cycles to less than 12 seconds.

Compress for spined channel detailing and ribbed impact zones, compression molded at 8–15 bar pressure for accurate reproduction of <0.5mm mold features. The components are molded at the same time using multi-station tooling, forming EVA foam cores and TPU outers in a 90-second cycle. At the same time, real-time pressure sensors adapt cavity-filling patterns and significantly reduce material flash by 22% compared with conventional vacuum systems. This process is imperative for CE certified protectors where accurate dimensional tolerances are mandated as per the EN 1621-2 specification.

Uneven cooling is still the leading factor in warpage of thermofom back protectors. Conformal cooling channels, strategically placed, accelerate heat dissipation rates up to 40%, particularly in thick-section areas adjoining shoulder straps. Recent simulations indicate active nitrogen cooling reduces distortion risks by 20–25% relative to passive air systems. Yet, fast cooling below 60°C, may trigger micro-cracks into the polymer matrices— which is a pivotal point to take in consideration for a multi-impact performance validation.

Laser-based automated thickness measurement systems are used in back protector production to achieve tolerances of ±0.1 mm over batches. These systems use spectral analysis for the detection of the risk of delamination in multilayered composites during thermoforming — key for EN 1621-2 impact-absorption requirements. PLC capability is integrated allowing automatic ejection of non-complying units and updating of SPC (statistical process control) dashboards every 15 seconds.

CE-certified manufacturers implement ANSI Z1. 4 sampling plans to ensure of 8% production batches are tested and documented in accordance with ISO 17025. New EU audits focus on traceable sampling periods — if you are running a production of 50,000 protectors, technicians will pull 12 off an hour for compression/shear testing with blockchain-logged data. This meets the European Commission’s 2024 updated PPE regulation, which mandates at least 95% confidence in the detection of any defect in PPE used in vital safety components.

The use of parallel processing has resulted in an 18–22% reduction in protector production lead times when compared to traditional linear methods. Overlapping the preparation of material and molding process allows for the performance of multiple operations at once and no loss of impact performance versus CE EN 1621-2. Intelligent scheduling software optimises resource use across several machining lines, resulting in a 34% reduction in idle tooling time for mass production. Real-time monitoring equipment also reduces bottlenecks by synchronizing mould temperature changes with downstream quality inspection.

Cross-trained operators make production lines flexible, reaching 92% utilization rate for machines in 24/7 back protector manufacturing cycles. With modular training courses for compression molding and automation thickness calibration, shift changeover time decreased by 41%. Simulated onboarding reduces skill acquisition time from 14 weeks to 6 days for thermoforming machine operators, vital to keep CE certification for all work shifts.

thanks to the optimisation of the material yield, manufacturers obtain a considerable saving on the costs of production of back protectors. CAD-based nesting algorithm reduces polymer sheet waste by 15-22%. This saves material and enables structures to keep their form with the help of compensated cut patterns. Some revisualising to help increase yield—real-time monitoring systems help by finding defects earlier, which can slash scrap rates 8-12% (percentage wise) over an entire continous production run.

Back protectors account for 25-30% of the overall manufacturing costs, in terms of energy. Moving to servo-electric molding machines reduces energy consumption by 35% compared to hydraulic systems. Smart HVAC set-ups with occupancy sensors reduce facility energy requirements by 18% while 12% of motion energy comes back to life with conveyor regenerative braking systems. On average, the payback on these improvements is less then 18 months through the realized dollar cost saving in energy and maintenance.

Twenty to forty per cent recycled polymers — such as post-consumer PET and reclaimed TPU — are now used by industry leaders in back protector cores, enabling EN 1621-2 impact resistance, while per unit saving of virgin plastic is as high as 32%. State-of-the-art compounding methods guarantee consistent materials performance, with pilots showing comparable energy absorption to conventional foams at a 16% lower density.

Progressive manufacturers utilize polymer recovery systems that recycle 92% of production scrap back into new protectors, slashing raw material costs by $0.18–$0.35/unit. Here end-of-life protectors are split into base polymers and additives through automated disassembly lines, and 85% material recovery rates are realized. To achieve full traceability between raw feedstock and finished product, the material is monitored in real time with RFID tags.

Polymer composites such as a hybrid TPU-fiberglass layer or carbon-fiber reinforced plastics are common due to their customizable stiffness and energy absorption abilities.

Although TPU is stronger, it is more expensive than EVA. A TPU-EVA hybrid can lower costs by 40% without losing protection effectiveness.

Thermoforming is crucial as it balances structural and ergonomic design through processes like vacuum and compression molding.

By adopting parallel processing practices, manufacturers can reduce lead times by 18–22%, improving overall production efficiency.

Hot News

Hot News2025-12-08

2025-09-15

2024-12-30

2024-12-23

2024-12-09

2024-12-02