The EN 1621-2 standard sets impact absorption benchmarks for back protectors, defining two performance tiers:

CE certification adds requirements like temperature resilience testing (-10°C to +40°C) and annual batch audits. Manufacturers must maintain 2% defect rates through statistical process controls to ensure consistent performance.

ISO 9001-certified factories achieve 34% fewer material defects (Occupational Safety Quarterly 2023) by enforcing traceability from sourcing to final inspection. The framework reduces production delays by 22% for large orders (10,000+ units) and aligns with regional safety regulations, minimizing warranty claims.

Bulk orders typically take 4–8 weeks, with optimized producers using just-in-time inventory and predictive analytics. Third-party logistics ensure 98% on-time delivery, even during demand surges.

Ethical sourcing requires full traceability of impact-absorbing foams and laminates. Many suppliers now offer digital chain-of-custody documentation (aligned with ISO 20400), and 63% audit Tier 2 suppliers annually. Blockchain tracking verifies material consistency for CE certification.

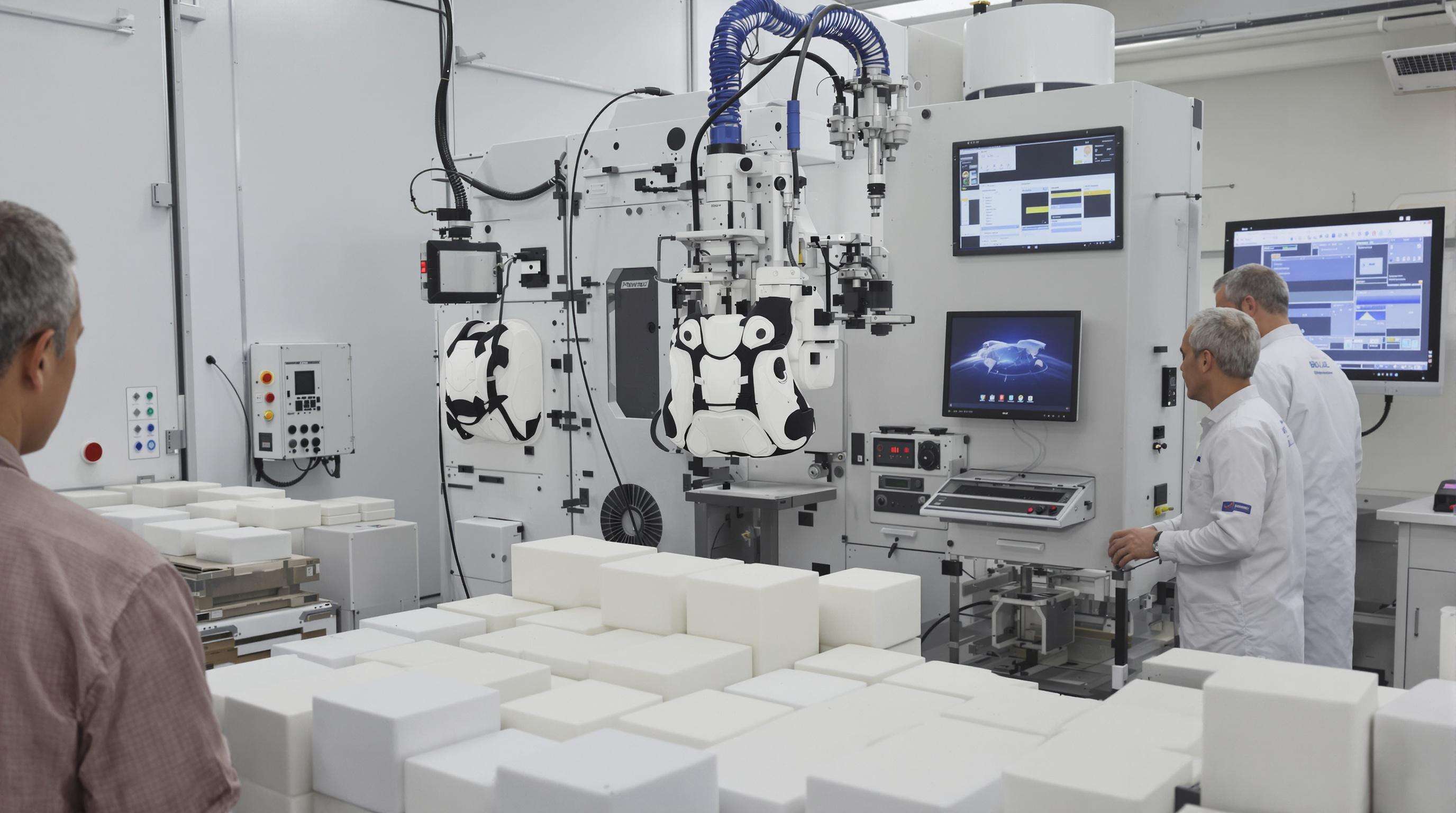

Flexible lines switch between CE Level 1 and 2 protectors in <90 minutes, maintaining 85% equipment efficiency. Automated nesting reduces material waste by 18%, while real-time pressure mapping ensures uniform impact resistance in high-volume batches.

Robotic impactors simulate 50-joule forces (aligned with EN 1621-2), with certified protectors showing 5% variance across batches. Automated systems check foam density (±2% tolerance) and shell integrity post-molding.

Quarterly recalibration (ISO 17025 standards) and stratified sampling for bulk orders (5,000+ units) maintain compliance without 100% inspection.

Blockchain-enabled digital twins track materials through production, achieving 99.6% shipment accuracy. FEFO algorithms prioritize aging materials, reducing warranty claims by 73% in climate-controlled storage.

68% of OEMs prioritize anatomical alignment, using pressure mapping to position shock-absorbing zones (<120 kPa resistance). Modular designs offer configurable lumbar support for motorcycle riders.

CAD-driven prototyping cuts design-to-production time by 40–60%. Five-axis CNC milling and additive manufacturing allow same-day adjustments for vent patterns or strap anchors while meeting EN 1621-2 standards.

Bulk buyers benefit from tiered warranties (1–3+ years for orders >5,000 units). Suppliers with fast claim resolution (48 hours) retain 78% of enterprise clients.

Regional hubs enable 72hr deliveries. Logistics partners must handle customs efficiently (20–25% of delays stem from documentation errors). AI-driven inventory forecasting cuts buffer stock needs by 30–40%.

Orders >5,000 units often get 15–20% discounts, but cost-cutting can compromise protection. Lower-grade foams reduce costs by 30% but increase G-force transmission by 18%. Smart buyers demand:

EN 1621-2 defines two performance levels: Level 1, which transmits 18 kN force, suitable for general use; and Level 2, reducing force to 9 kN, ideal for high-velocity impact protection.

CE certification includes additional requirements like temperature resilience testing ranging from -10°C to +40°C and mandates annual batch audits. CE also enforces a 2% defect rate through statistical process controls.

ISO 9001 certification helps reduce material defects by 34% and cuts production delays by 22%. It ensures traceability and minimizes warranty claims by aligning with regional safety regulations.

Modular production lines offer flexibility, enabling quick switches between different product levels, maintain 85% equipment efficiency, and reduce material waste by 18% through automated nesting.

Blockchain enables digital twins for tracking materials through production, achieving high shipment accuracy and reducing warranty claims by ensuring material consistency and prioritizing older materials for use.

Hot News

Hot News2025-12-08

2025-09-15

2024-12-30

2024-12-23

2024-12-09

2024-12-02