Effective back protector design begins with material science principles that balance protection, durability, and wearer comfort. Industry leaders prioritize three foundational criteria when engineering spinal safety systems.

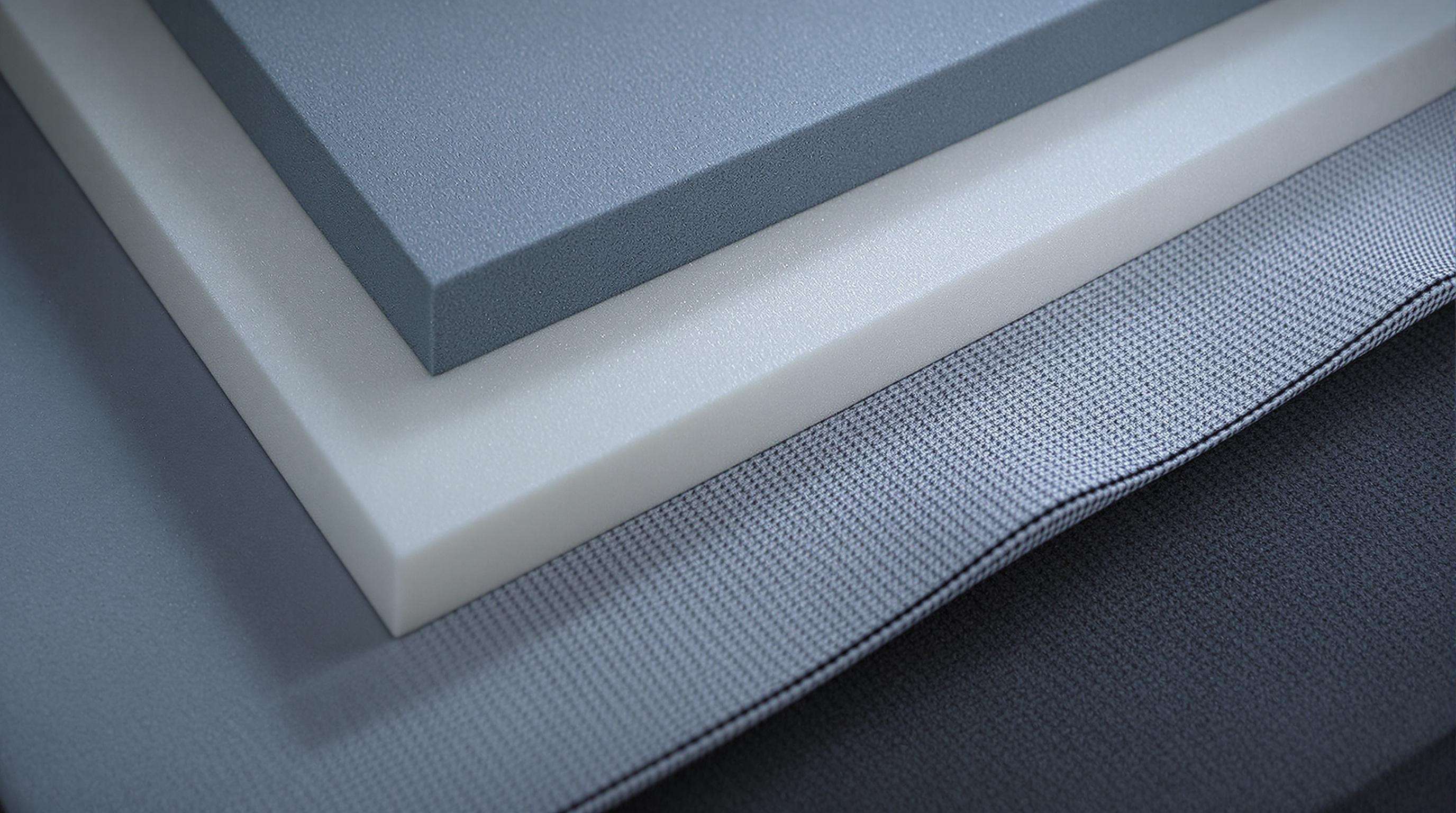

Expanded polypropylene (EPP), high-density polyethylene, and high-density polyurethane are commonplace, with energy-absorbing properties (density, 50-90 kg/m³) Dispersal of energy across the back protector. 80 kg/m³ polymers can grant a 70% reduction in peak impact forces versus traditional foam materials, according to a 2023 Impact Materials Study. Manufacturers can’t sacrifice flexibility for density — too-stiff materials limit movement, while less-dense ones can’t withstand high-energy impacts. In certification tests according to the European safety standard EN1621-2, the protector material must transmit a force of ≤18 kN, obliging for control volume to density calculations.

Advanced composites use a matrix whose properties are superior to those of, for example, a normal polymeric material like a natural polymer such as rubber or a plastic such as a plasticene. These extraordinary materials are used in various applications. Advanced composites are used in a variety of high-performance applications. Cross-woven in 15-20 layer spread tow multi-axial systems are highly impact resistant in all directions and resin infusion processes remove any intersection of fibers once a source of potential weakness. According to recent market analysis, now composites represent 62% of premium back protector materials having 40% weight saving vs. solid polymer plates.

Base layersneed fabrics with vaporpermeability≥500g/m2 /24hr (MVTR). Laminates of hydrophobic outer fabrics, capillary action midlayers, and antibacterial inner meshes that keep humidity retention <15% in extended use. According to a 2024 Thermometer Comfort Study, such systems lessen heat stress by 58% in equestrian applications, versus typical polyester liners.

Impact resistance testing protocols for back protectors form the cornerstone of rider safety systems, ensuring protective gear meets rigorous performance benchmarks. Contemporary certification frameworks combine standardized laboratory evaluations with real-world collision simulations to validate materials and designs.

The American Society for Testing and Materials (ASTM) and European Conformité Européenne (CE) standards specify the minimum level of impact resistance required for back protectors to gain certification. Compliance with the EN 1621-2 application requirements necessitates extensive test sequences for determination of force transmission limits via synthetic impactors against protectors impinged by impactors at controlled velocity. All major program accreditations demand revalidation on an annual basis of test equipment and the operator’s competence along with third-party audits of the manufacturer to ensure it maintains its certification. New updates to CE standards have added -10°C low temperature performance tests, in addition to the standard ambient condition tests.

The impact tests today simulate realistic crashing mechanisms of protectors in that they are exposed forces from lateral, vertical and oblique directions. Impact is replicated by pneumatic actuators at speeds of up to 9 m/s, and triaxial sensors measure force distribution on the surface of protectors. These methods uncover points of weakness and areas for improvement in composite layering systems.

ACL spaces evaluated energy dissipation using a standardized series of mass-drop tests and determined force attenuation across the protector assemblies. Calibrated sensors measure maximum impact forces in composite layers with pass/fail limits based on worldwide safety standards. Studies on force transmission analysis have shown that, relative to conventional polymeric matrices, advanced foams significantly minimize the transmitted energy 1, 6, 9, 17, 22. The testing protocols ask for six successive impacts on the same protector zone at 50J energy levels to prove repeatability of the material when subjected to cyclic loading.

Ergonomic design criteria of back protectors: Three key factors Material flexibility is used to achieve a balance between spinal protection and user mobilityAnatomical shaping results in an optimum ergonomic fit for the human body Ventilation is the third main feature of ergonomically designed back protectors. Advanced materials, such as viscoelastic polymers and closed-cell foams, conform to body shape while resisting impact and have been shown to consistently provide 94% impact energy absorption efficiency over temperatures from -20°C to 40°C.

Equally the adjustable segmentation to modular designs maintains removable regions that may be re-configured by users for the area-based protection, whilst retaining the 12 mm minimum thickness for impact absorption whereas up until now, the modularity feature had been limited to designs. These anatomical shaping methods take gender specific spinal curvature into account, reducing pressure points by up to 33% over traditional unisex pads. Responsive integrated moisture-wicking liners with 360° airflow channels solve hot issues -- a key takeaway, considering market study reveals 68% of those surveyed identify breathability is the top priority during extended wear.

Back protectors must meet rigorous international safety regulations to ensure consistent protection across high-risk activities. These standards govern material performance, design ergonomics, and impact mitigation capabilities. Manufacturers prioritize certifications like EN 1621-2 and ASTM/CE to align with global market requirements while addressing sport-specific risks.

The EN 1621-2 standard mandates back protectors reduce transmitted impact forces to ≤18 kN (Level 1) or ≤9 kN (Level 2) during vertical drops of 4.43 Joules. A 2022 study on motorcycle safety protocols found EN 1621-2-certified protectors lowered spinal injury risks by 33% compared to non-certified alternatives. Compliance involves:

Motocross back protectors typically require Level 2 EN 1621-2 certification due to higher-speed crash forces (avg. 45-75 km/h), while equestrian gear adheres to BETA 2018 standards focusing on low-profile designs for rider mobility. Key divergences include:

| Parameter | Motocross | Equestrian |

|---|---|---|

| Impact Test Energy | 50 J (ASTM F355) | 30 J (BETA 2018) |

| Coverage Area | T1-T12 vertebrae | T1-L3 vertebrae |

| Flexibility Rating | Semi-rigid | Articulated panels |

Cross-industry analyses show 68% of dual-sport protectors sacrifice impact ratings to meet equestrian flexibility demands.

Back protector manufacturers verify impact uniformity by performing random batch testing on 15–20 units from each production cycle. Test procedure simulates compression loads over 50 kN (EN 1621-2 Standard) while recording force distribution on nine anatomic zones. According to a study on protective gear in 2023, compliant systems retain 98.6% variance in impact force consistency (inter-batch) through SPC (Statistical Process Control) monitoring. Catastrophic failure modes such as foam debonding or reinforcement pull-out will initiate the immediate holding of production and will not be restarted until the root cause(s) have been corrected.

Advanced vision systems now scan 100% of back protector components using dual-spectrum infrared spectroscopy to detect material inconsistencies as small as 0.2 mm². Three-stage defect classification protocols automatically reject units with:

Back protectors commonly use materials such as expanded polypropylene (EPP), high-density polyethylene, high-density polyurethane, and advanced composites.

Back protectors must meet standards set by organizations like ASTM and CE. These include multi-directional impact tests and energy absorption metrics verification processes.

EN 1621-2 certification ensures back protectors effectively reduce impact forces, lowering spinal injury risks significantly in tested scenarios.

Material flexibility ensures a balance between spinal protection and user mobility, crucial for ergonomic comfort and effective protection.

Hot News

Hot News2025-12-08

2025-09-15

2024-12-30

2024-12-23

2024-12-09

2024-12-02