The EN 1621-2 standard specifies two protection tiers for back protectors:

Testing involves striking protectors with a 5 kg impactor at 4.4 m/s, simulating falls on hardpack snow. Materials must maintain performance across -10°C to +40°C, ensuring reliability in alpine conditions. Recent updates require protectors to cover ≥ 500 cm² of the thoracic spine while limiting thickness to ≤ 45mm for mobility.

Ski schools must follow a three-phase certification workflow:

Certified equipment receives a unique EN 1621-2 QR code linking to test results. Rental fleets must revalidate protectors every 24 months through abbreviated impact tests. Non-compliant units show visible foam compression or cracked armor plates during routine inspections.

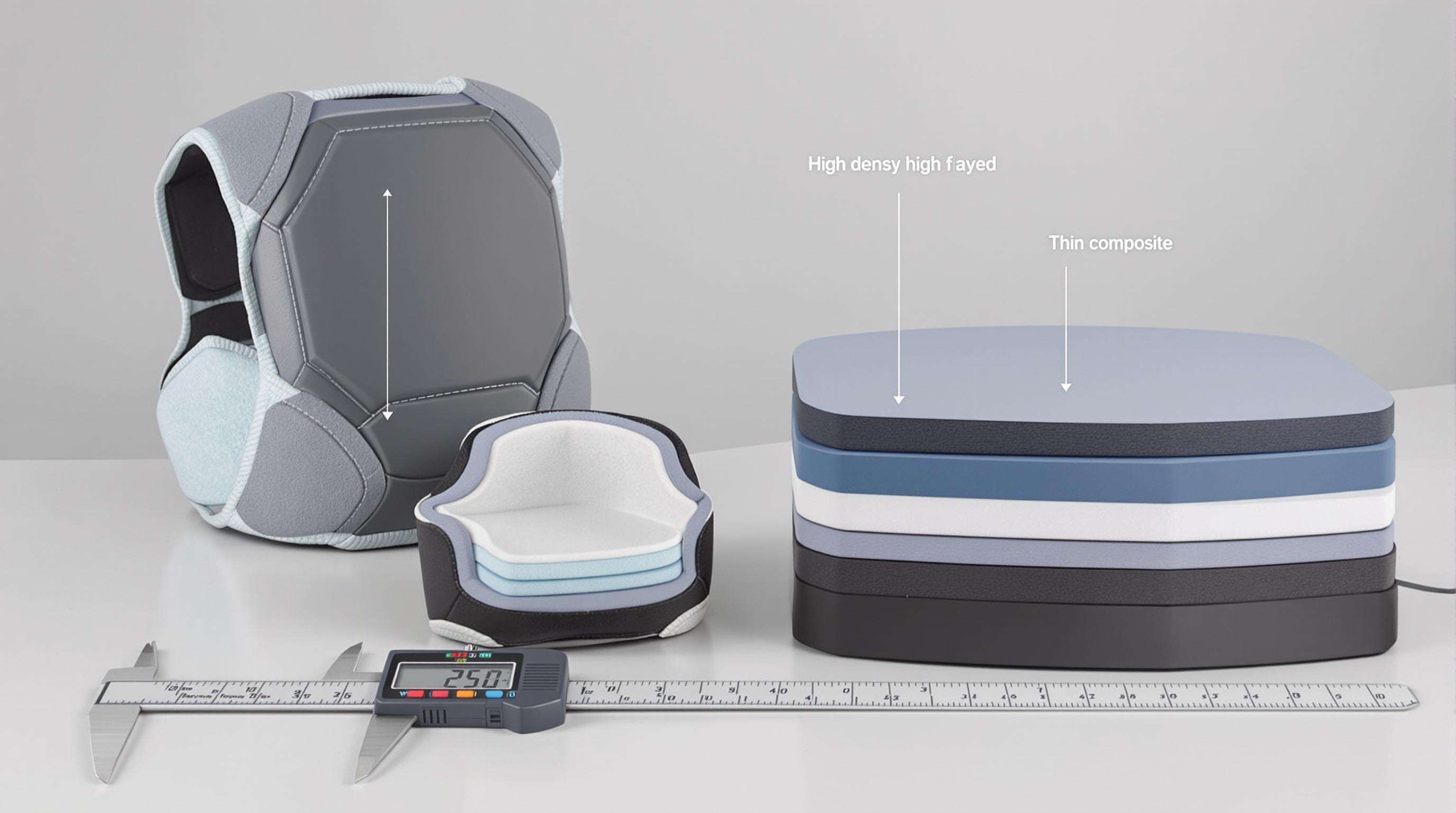

The higher demands on modern back protectors are anatomy and effect in a2 balance. EN 1621-2 certification calls for at least 600 cm² of protective surface to cover the thoracic and lumbar spine. Material thicknesses between 9–12mm are required dependant on composition and high-density foams can be 40% more effective at absorbing impact than standard polyethylene equivalents. State of the art laminate composites now offer up to Level 2 protection (≤ 18 kN force transmission) whilst in sub-3mm profile form essential to unrestricted ski movements.

Airbag systems must be deployed electronically within 3 seconds to be FIS certified as well. At rider impact, the collar inflates in less than 0.1 s which allows 0.7 s for complete inflation before secondary impacts could occur-this is important for safety, because 73% of spinal injuries are the result of multi-impact collisions. The current compressed gas cylinders perform in 2.1–2.8 s at -20°C conditions in order to support timely deployment, while the moisture-resistant trigger mechanism is used to prevent accidental activation in a snowy environment. Three Consecutive Inflation Tests Failing Protectors failing three consecutive inflation tests must have the cartridge replaced immediately under the ISO 13485 maintenance guideline.

The Fédération Internationale de Ski (FIS) has transformed ski safety through binding equipment mandates that now dictate rental program operations. These protocols require operators to reconcile compliance costs with consumer accessibility while ensuring adherence to updated protective gear standards.

Over a period of five years (2020-2025), FIS back protector rules were transferred from a voluntary predator to a mandatory requirement. The original guidelines allowed rental fleets to keep using legacy gear, but 2023 amendments requires EN 1621-2 certification for all new purchases. This change came after the analysis revealed that spinal injury rates in non-certified gear were 3.2× higher than what was seen in certified options during controlled impact testing.

By 2025, FIS expanded enforcement beyond elite competitions to include recreational programs partnering with certified ski schools. This phased implementation created a $17M retrofit market for North American rental operators alone, accelerating adoption of modular protector designs.

Renters have their own challenges when it comes to FIS compliance; for businesses that operate a rental (or hire) program in which the users are constantly in flux, FIS compliance becomes a percentage game. An industry survey published in 2024 found that 68 percent of operators find it challenging to test protector fit across multiple body types, and 41 percent report incomplete staff training on airbag system diagnostics. High turnover of seasonal workers compounds the lack of quality control and poor harness adjustment accounted for 23% of failures on protectors in rental-use applications.

Civil liability disputes further complicate enforcement–32% of ski-related injury claims now cite inadequate safety equipment briefing as a contributing factor. To mitigate risks, leading resorts have implemented barcode scanning systems to track protector inspection histories and automate compliance reporting.

Back protectors alone are a staple safety item for children in ski racing programs, for young bodies are sensitive and still developing. The protectors are anatomically designed and do not, as opposed to most other adult protectors, absorb the impact energy and thus comply with the EN 1621-2 norm. The tourist industry: no longer an innocence abroad ON SNOW LEADERS now design built-in protection that is actually comfortable to wear because they know 61% of young skiers do not use protective equipment due to their perception that it is too big and not cool' (Ski Safety Journal 2024).

Proper sizing is critical for pediatric back protectors to ensure energy dispersion across vulnerable spinal regions. Key design considerations include:

A 2023 biomechanical study found improperly fitted youth protectors reduced impact absorption efficacy by 40% compared to custom-sized equivalents.

A three-year analysis of 620 participants in European youth ski clinics revealed dramatic safety improvements after implementing certified pediatric back protectors:

| Metric | Pre-Implementation | Post-Implementation |

|---|---|---|

| Spinal injury rate | 12.7% | 1.9% |

| Equipment compliance | 48% | 92% |

| Program retention | 76% | 89% |

The 85% injury reduction correlated directly with mandatory protector policies and staff training on proper fitting techniques. Programs requiring weekly equipment checks maintained 100% compliance throughout the study period.

Ski rental operations balancing safety mandates with operational efficiency require systematic approaches to equipment management. Leading resorts now implement standardized protocols that address certification validation, staff competency, and maintenance tracking – key factors influencing both liability protection and customer safety outcomes.

Frontline teams receive quarterly workshops on detecting:

| Component | Inspection Frequency | Acceptance Criteria |

|---|---|---|

| Gas cartridge pressure | Daily | ≥ 200 bar at 15°C |

| Seam adhesives | 50 rental cycles | No visible peeling under UV light |

| Battery charge | Weekly | Holds ≥ 8 inflation cycles |

| Digital logging systems automatically flag protectors exceeding wear thresholds, ensuring 100% traceability for auditors. This protocol reduces airbag failure rates by 67% compared to manual tracking methods. |

Retailers offering ski rental are caught up in the tricky equation of EN 1621-2 certified protectors costing between €180 and €420 per unit versus slim margins. The advanced protective gear market analysis indicates that manufacturing costs for high-end materials, such as memory foam composites and reactive polymer layers represent 60% of the product retail price. The seasonal aspect of the work is said to "crash the test" of operators who are forced to keep vehicles in service in excess of their specified life, but still must meet crash test requirements – a balance that necessitates daily inspection of armor plates and annual testing of foam density to avoid getting bad armor when the supply at peak demand.

The financial advantage of certified back protectors is proven through measurable ROI in liability risk reduction with 12–18% premium discount being offered by insurers on a pay back for who fund a fleet that operates at 95%+ compliance levels. According to data from the North America back protectors market research, certified gear has helped resorts see 40% fewer spinal injury claims than the uncertified ones. This business case model, which provides for cost-versus-benefit alignment, motivates carriers to want to focus on airbag system recertifications and moisture-wicking liner replacements, in effect turning safety investments from liabilities into prudent guards against catastrophic claims.

EN 1621-2 certification is a standard that specifies the safety requirements for back protectors, particularly for skiing and snowboarding, by setting limits on the amount of force the protectors can transmit.

EN 1621-2 specifies two protection levels: Level 1, which limits force transmission to ≤ 18 kN, and Level 2, which limits transmission to ≤ 9 kN, usually required for competitive sports.

Ski rental fleets must revalidate back protectors every 24 months through abbreviated impact tests.

FIS mandates dictate compliance with updated protective gear standards, increasing operational costs but improving safety standards, particularly through the adoption of EN 1621-2 certified back protectors.

Key considerations include adjustable torso length, contoured shoulder straps, and breathable foam composites to ensure proper fit and safety for children.

Hot News

Hot News2025-12-08

2025-09-15

2024-12-30

2024-12-23

2024-12-09

2024-12-02