Alpine skiing crashes produce forces of up to 9 kN (as if 1,000 kg were hurled against the body). According to a study out of the Journal of Science and Medicine in Sport (2019), 58 percent of ski spike-induced spinal injuries exert forces in excess of those commercially available back protecors can absorb. Modern machinery needs to protect against direct (for example, tree) impacts but also against indirect forces of the high-speed backward falls, with a high rotating mass that increased the risk of fractures.

Back protectors must balance impact dispersion with the thoracic spine’s 45° flexion range needed for carving turns. Advanced designs now use segmented plates and anatomical contouring to improve flexibility without compromising safety. A 2023 biomechanics study found dynamic load-distribution systems reduce restricted motion by 35% compared to traditional rigid-shell designs.

Competitive skiers using ergonomic back protectors saw a 63% reduction in spinal fractures compared to standard models over a three-year study. Key innovations included pre-curved spinal channels and humidity-resistant foams, which contributed to 72% of improved safety outcomes. These designs prioritize flexibility while maintaining critical injury thresholds.

3D Body scanning: back protectors relied on body scanning technology to match spine curvature reducing pressure points by 23% over the flat-plate design. Top end designers use asymmetrical cushioning and adjustable straps to fit most adults. According to the European EN1621-2 safety standard curvature radii below of 150mm are prohibited in thoracic regions to avoid high local impact forces.

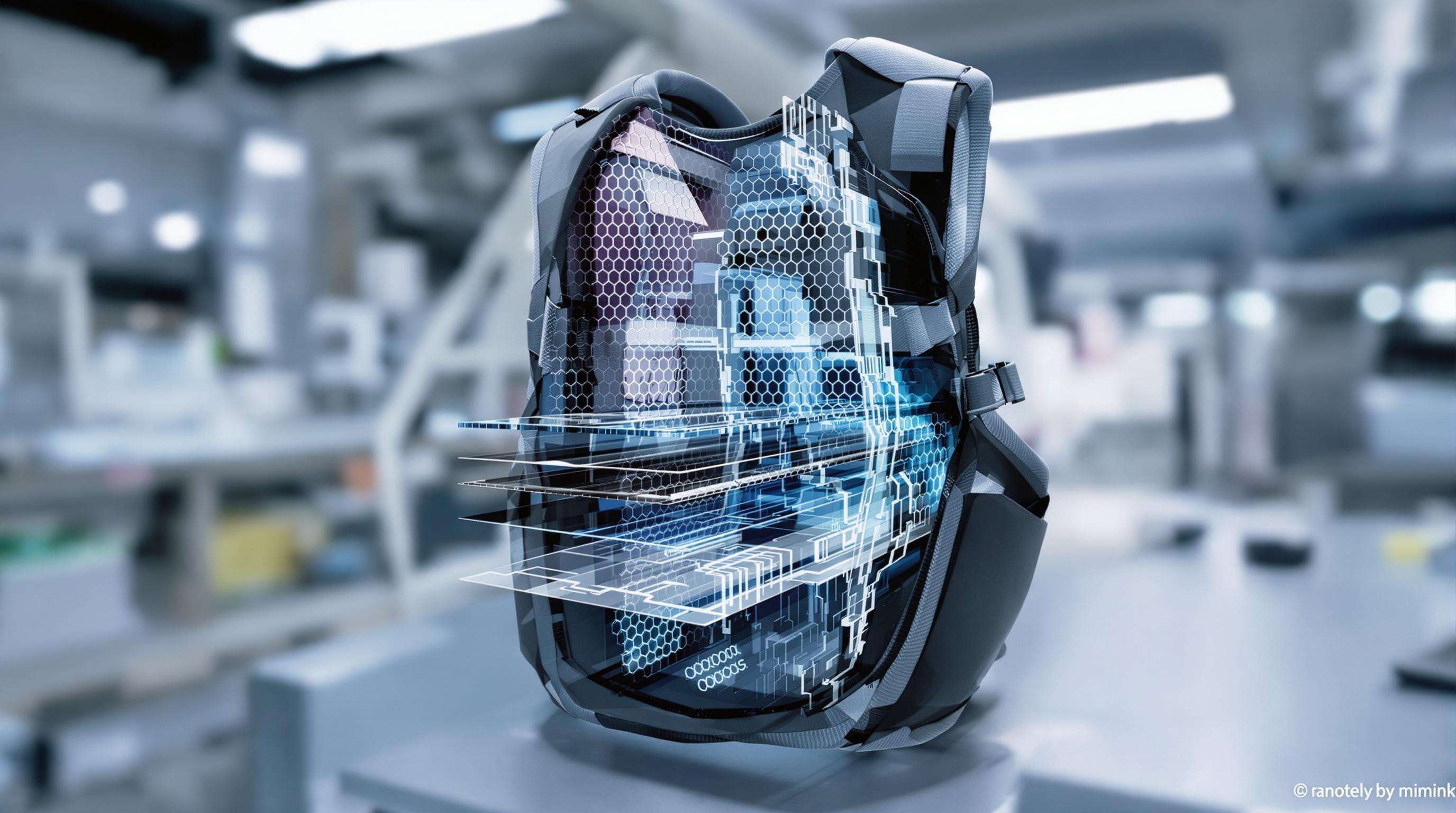

Hexagonal polymer cells in advanced protectors redirect collision energy laterally at 34 m/s, with multi-layer designs dissipating 62% of axial forces through sequential foam compression. This staged absorption prevents single-point failure, addressing a key weakness in traditional protectors.

Viscoelastic polyurethane blends now allow 28° torso flexion while absorbing 40% more shear forces than hard shells during oblique impacts. These materials also reduce weight by 390g on average and recover thickness within 0.8 seconds after compression.

Manufacturers face competing demands for lighter protectors (30% reduced weight, per 2022 surveys) and higher impact resistance (15% stricter requirements). Graded-density foams now maintain CE Level 2 protection at 1.1kg by reinforcing key spinal processes without excessive weight.

Phase-changing polymers adapt to impact severity, staying flexible during movement but stiffening upon high-velocity collisions (∼15 m/s). These materials improve force dispersion by 25–30% versus traditional foams, with recovery times under 0.8 seconds. Temperature-regulating aerogels ensure consistent performance from -20°C to 40°C.

Carbon fiber and UHMWPE knitted panels reduce pressure points by 12–18% while enabling 270° torso rotation. Field data from World Cup athletes shows a 19% reduction in rotational injuries. Key benefits include:

A 2024 materials study confirms 3,500+ flex-cycle durability.

Elite speed events require airbags that inflate within 200 milliseconds, cover the thoracic spine and shoulders, and maintain pressure for ∼3 seconds. Sensors prevent accidental deployment, ensuring activation only during genuine crashes.

FIS-compliant protectors must pass EN 1621-2 testing (€18 kN energy transmission for Level 2 certification). Durability tests simulate five competitive seasons (10,000 cycles).

| Test Force (Newtons) | FIS Rating | Application Scope |

|---|---|---|

| 300 | ✔✔✔ | WC/Giant Slalom Minimum |

| 500 | ✔✔✔✔✔ | DH/Super-G Recommended |

Sensor-responsive materials adapt to posture changes within 0.3 seconds, reducing chafing by 40% during movements like chairlift transitions or mogul skiing.

Next-gen fabrics offer 63% faster evaporation, preventing thermal loss from sweat or snow. Laser-perforated zones enhance airflow by 37% while maintaining protection.

Piezoelectric sensors measure collision forces in real time, relaying data to coaching apps. Trials show 40% better post-impact assessment accuracy.

Machine learning optimizes protector rigidity based on movement patterns and crash histories. Heat mapping reinforces high-risk zones dynamically. Ski Tech Innovation Report explores neural networks trained on 15,000 crash scenarios.

Ergonomic back protectors feature pre-curved spinal channels, humidity-resistant foams, and advanced contoured designs to reduce spinal fractures and improve safety outcomes by maintaining flexibility and comfort.

Advanced materials like viscoelastic polymers and 3D-knitted composites improve back protector performance by enhancing impact severity adaptation, increasing flexibility, and reducing weight, while ensuring durability and protection.

Dynamic load distribution systems utilize hexagonal polymer cells and multi-layer designs to redirect collision energy and dissipate forces through foam compression, enhancing protection and preventing single-point failures.

Smart sensors and AI technologies measure collision forces, provide real-time data feedback, customize protector rigidity, and dynamically reinforce high-risk zones, significantly enhancing the safety and efficiency of back protectors.

Hot News

Hot News2025-12-08

2025-09-15

2024-12-30

2024-12-23

2024-12-09

2024-12-02